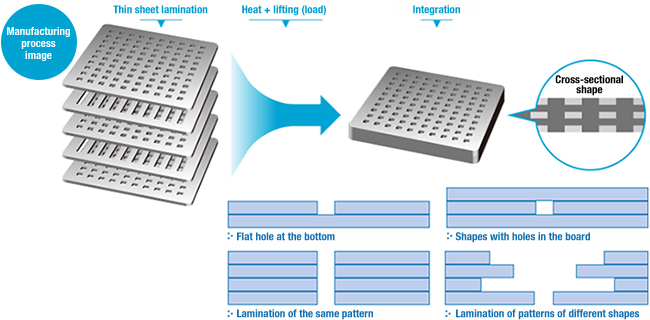

Diffusion Bonding

Diffusion bonding

By stacking multiple thin metal plates made by photoetching and diffusion bonding at the atomic level of the metal, we can achieve three-dimensional molding that is difficult with etching, including fine holes and thickness exceeding the processing limit, in order to create products with a high aspect ratio that cannot be achieved by etching, or cutting and machining alone.

Advantages of processing by diffusion bonding

・ High strength due to lamination of thin plates and little change in product dimensions

・ Compared with other construction methods, mass production is possible, and a reduction in manufacturing cost can be achieved

・ Complicated shapes, such as deep holes, tapered holes, and flow path structures can be manufactured in any shape

Joinable materials

Stainless steel + stainless steel

Example; SUS304 + SUS304 SUS430 + SUS430

42 alloy + 42 alloy

Amber + amber

Titanium + titanium

Copper + copper

Product pictures and applications

| Fuel cell separator | Evaporation mask | Suction plate |

| Carrier tape | Semiconductor manufacturing jig | Electronic components |

| Various filters | Heat exchanger related | Fuel cell related parts |

| Wire bonder | Heat sink, etc. |